Makers of Tar Valon - Polegnyn Nemeara

Author: Raevyn Tsornin

Published: March 16 2021 Tar Valon Times Blog Link

This month we are getting to know Polegnyn Nemeara (Nem), Aes Sedai of the Blue Ajah. Among Nem’s artistic hobbies are pottery.

Tar Valon Times: What is the basic set up needed for pottery at home?

Polegnyn Nemeara (Nem): A basic setup at home would essentially be a bag of clay. There are usually “maker spaces” that will allow people to rent space inside a kiln for their work to be hardened into ceramic material (aka “firing”). There are different types of clay made for different temperatures and for different purposes so it’s best to find out specifics from the place willing to fire one’s work before starting anything.

Anything around the house or in one’s yard to make textures and trim clay is also useful. That’s the nice thing about working with materials thousands of years old. Tools do not need to be fancy! 🙂

Working in a well ventilated space is also important. Small particles of dust can get into one’s lungs and eventually cause serious health issues. It’s not advisable for dust to get into spaces where one eats or drinks either.

TVT: How strong/hot and large is your kiln?

Nem: I have two kilns. One is a small Home Artist kiln (HA) traditionally used to make ceramic doll forms. I mainly use it to bisque (turn raw clay into ceramic material) items around 1900°F. The HA kiln is only about 12 inches squared and good for small items like low-fire glaze tests, a couple of my wall decorations or other small projects. Tests can be made at a quicker rate instead of having to wait and fill or only partially fill the second, larger kiln.

The second kiln is 23x27inch (interior) Paragon kiln (c. 1968) that can reach up to 2300°F. I refer to it as “Ishmael”. Since I use it for most of my glaze and higher volume firings, it truly can be a “betrayer of hope” as sometimes those glaze results are just not what I hoped for after such a long wait.

Affectionately known as Ishmael!

Pieces waiting for their turn in the small kiln.<br?

TVT: Do you pottery wheel or do you use a slip and mold?

Nem: I use both pottery wheel and slip casting (using molds) methods depending on the idea. The pottery wheel is much more efficient with creating circular forms than building each piece by hand. I usually save making forms on the wheel during warmer months due to the water involved with shaping the clay. I do use the wheel during cooler months to trim slip casted pieces.

Slip casting is an even more efficient technique and also creates much more consistent results. Even though slip still contains water, I usually save this process during milder winter months.

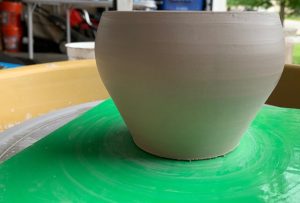

Fresh off the pottery wheel after its bottom has been trimmed.

Slip cast cups and pedestals still in their plaster molds.

TVT: How long does a piece need to dry before firing? or if it doesn’t what is the process from beginning to end – like what material do you use how long does it sit in the kiln etc?

Nem: The time it takes for a piece to dry well enough to be put in a kiln really varies between items and the amount humidity of one’s weather. Pieces are supposed to be “bone dry” meaning it contains absolutely no moisture in the clay before they are ready for the kiln. Otherwise the kiln can cause moisture still in the clay to vaporize, causing cracks or, worse, explode and potentially damage the interior of the kiln or other work. Time needed for this varies, but one can usually tell if it’s ready when the piece is room temperature. Even then, extra precautions need to be taken for thicker pieces.

The time pieces spend in the kiln also varies. General firings can range from 8–11 hours, but it usually takes at least 24 hours for a kiln to cool enough to be able to handle glazed pieces. Again, room temperature is ideal to avoid possible cracking or other glaze defects.

Clay with moisture still in it (left) and clay that is bone dry (right). Coloring varies depending on the type of clay.

Freshly glazed pieces.

Glaze test tiles fresh after a glaze fire.

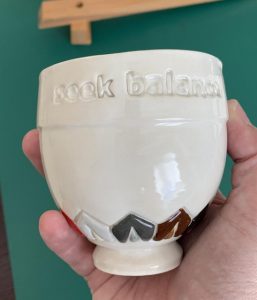

A finished slip cast and altered cup.

TVT: What piece are you most proud of?

Nem: The earliest piece I’m most proud of is a bowl made in my Ceramics 1 course in 2004. The class focused on building forms by hand. It ignited my love for clay, and taught me that pottery can be fun, relaxing, and offers challenges which I enjoy troubleshooting. My mom uses it at her house.

A much more recent piece I’m most proud of is one I’ve been working on for several years for the TarValon.Net community. This series of cups is still in development, but here are some casual photos of the proof-of-concept. I’m proud of these cups because of their extensive use of my second love, 3D printing.

Follow along with Nem’s progress at Rhodelander Ceramics!